Caging a 280zx

In an earlier post, I talked about the work we did to strip the interior of our 1981 Datsun 280zx Lemons build. In this post I’ll share some of the progress pictures, and excellent work done by our builder, Dan from The Gunbarrel Cobras. We’ve paddocked next to these guys several times and they’re clever with their cars, stupid fast when not blowing up, and good company at the track.

Cages in racecars have clear applications in safety. In the event of a rollover, a collision, or a particularly catastrophic off-course excursion, the driver is protected. Hard to overstate what a big deal that is. Something we all really appreciate about Lemons, is they do not screw around with safety. The rules are extremely clear, concise, and the enforcement of them during inspection is rigid. If you cage isn’t safe, you aren’t racing. If Lemons ever gets lax on these rules, we aren’t racing.

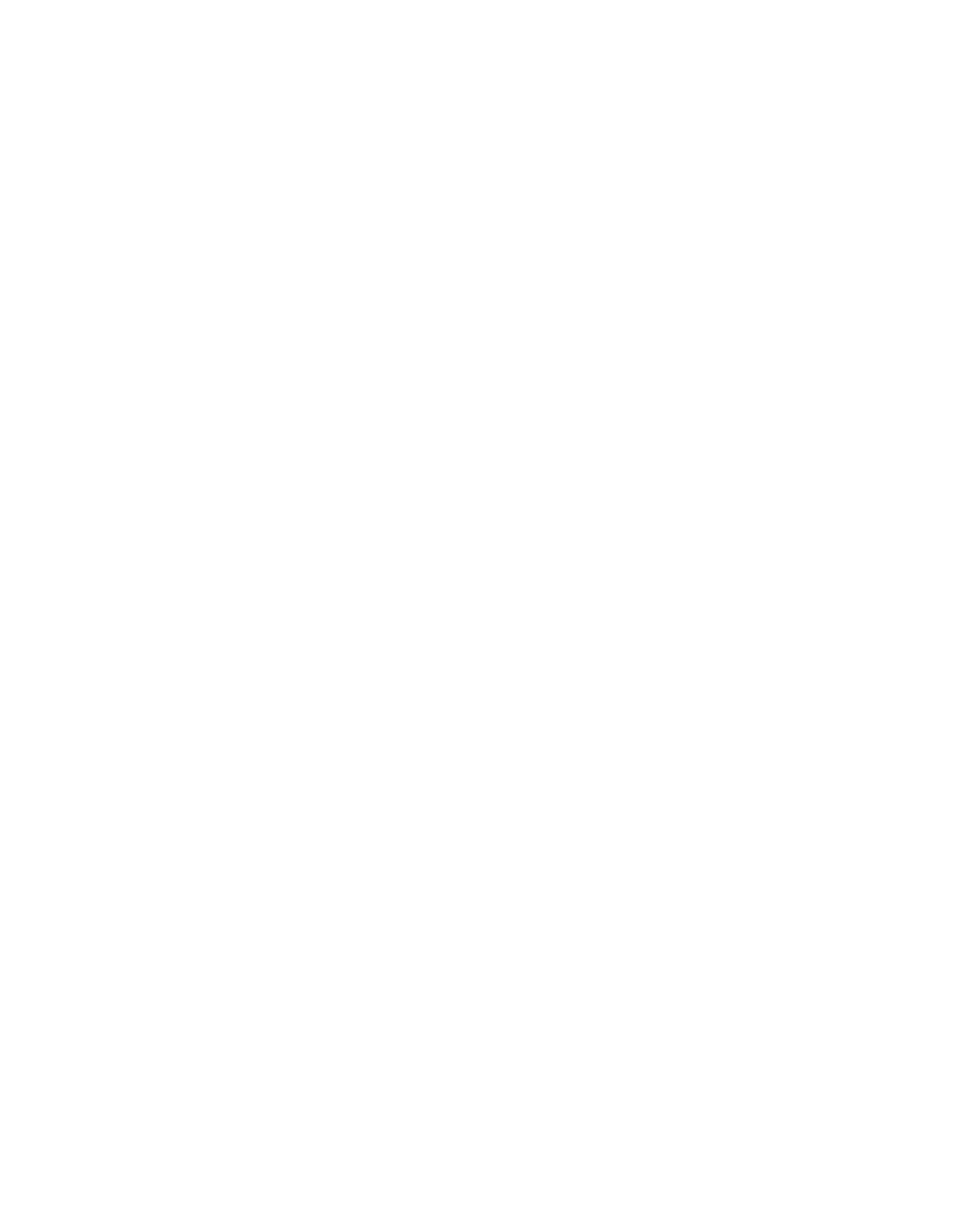

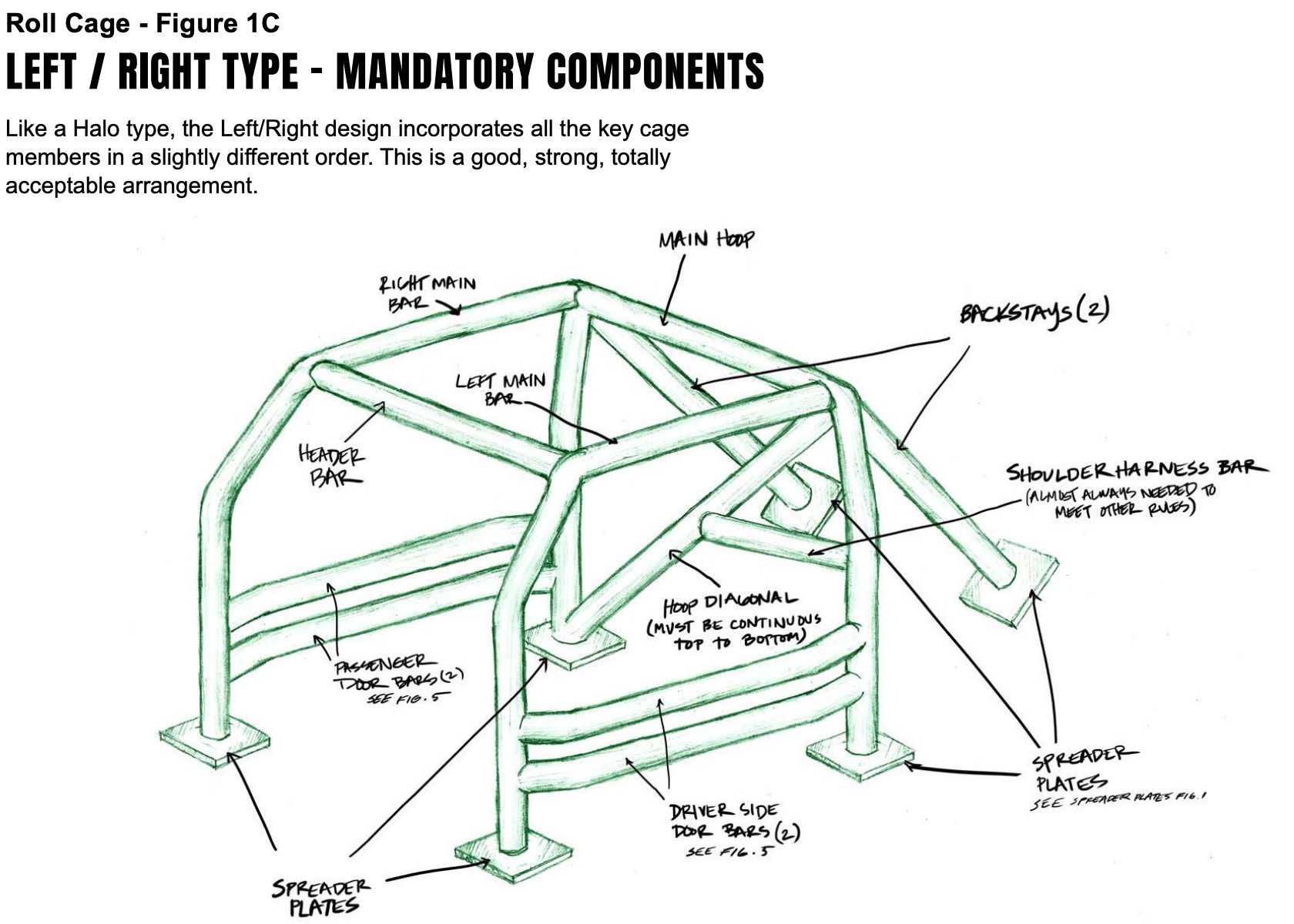

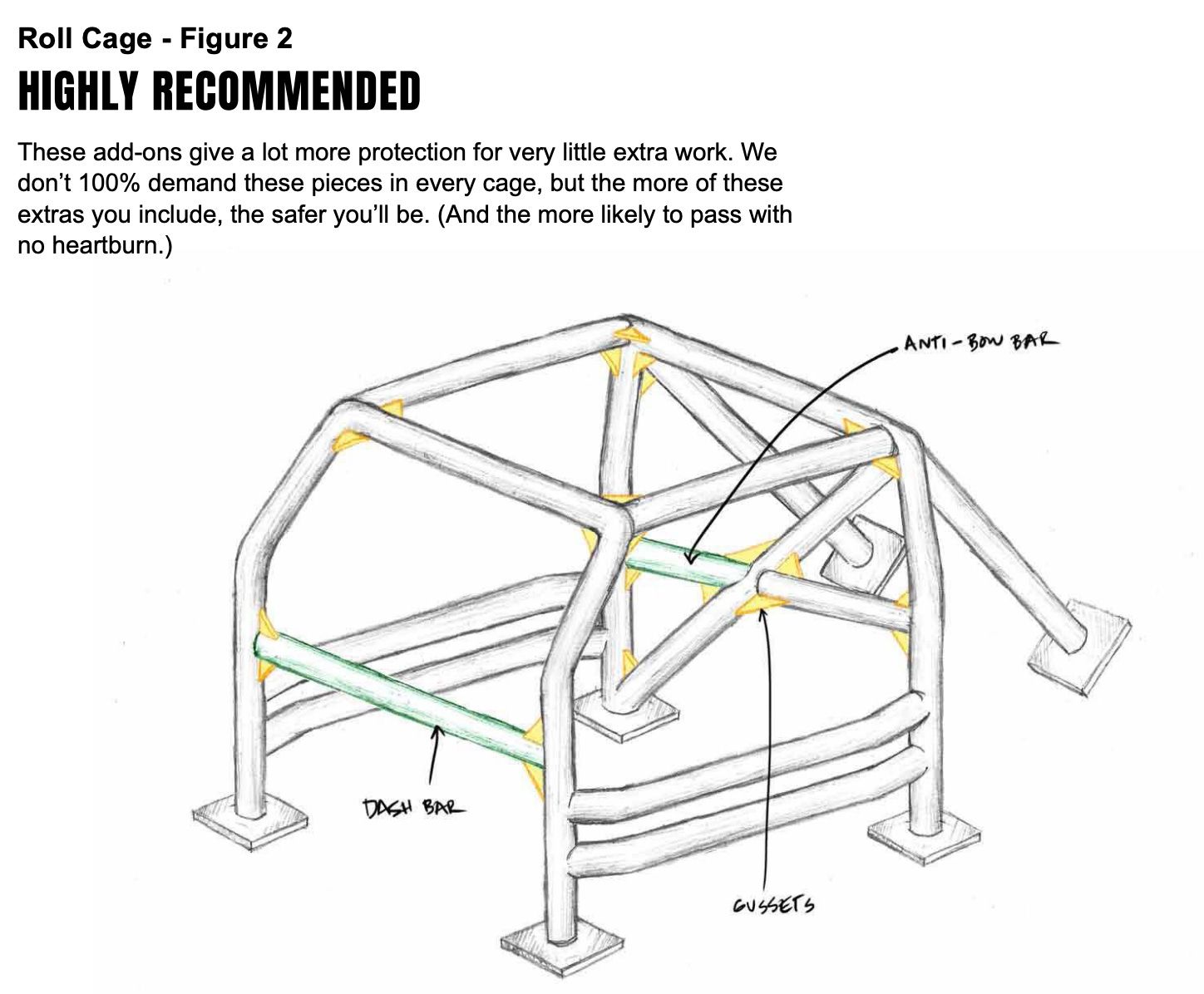

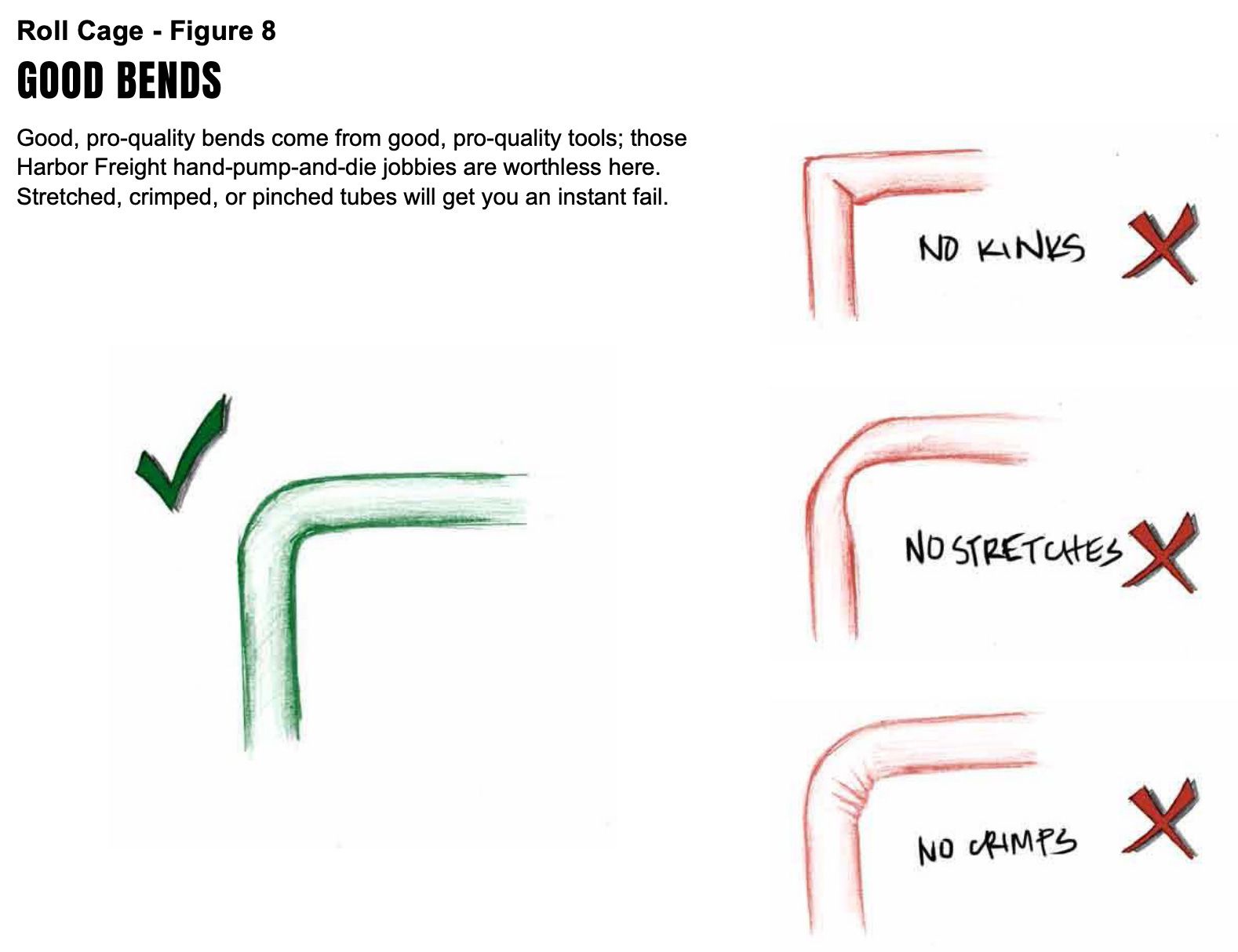

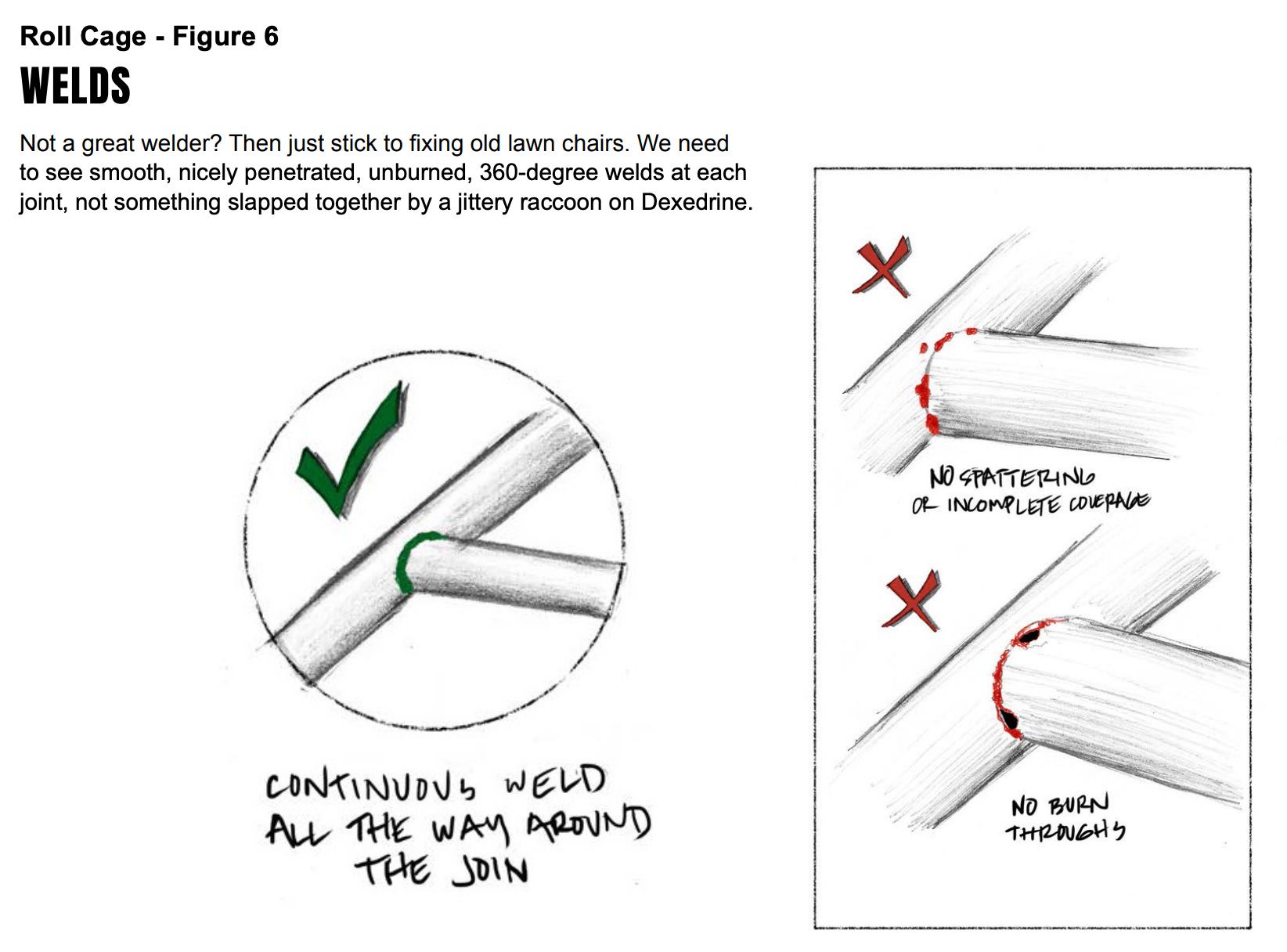

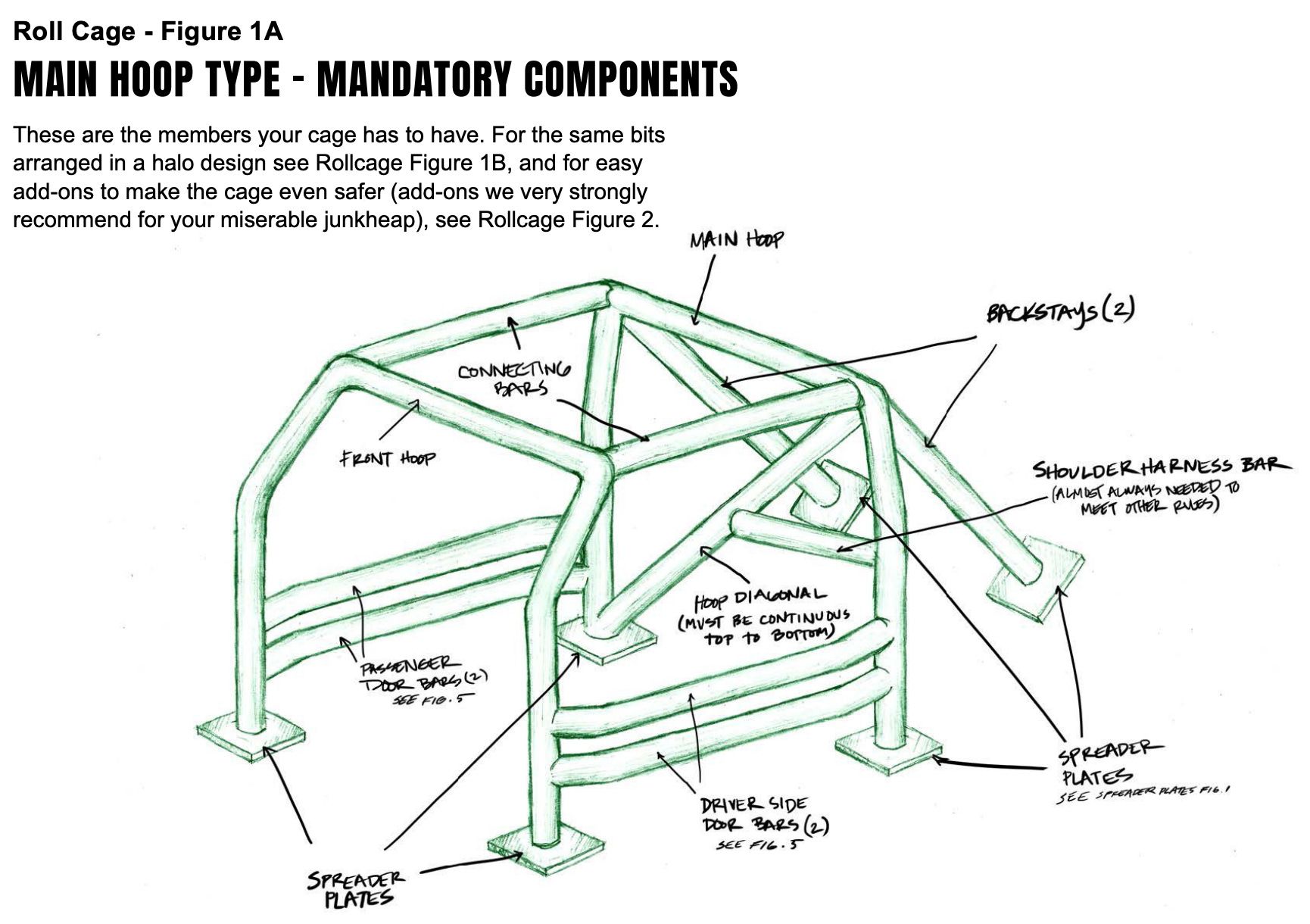

The How Not To Fail Lemons Tech pdf has some great illustrations for do’s and don’ts, and what constitutes a professional cage installation.

Happily, Dan has experience building cages that pass tech, and he got to work on our project. Less happily, he also had some holes to patch along the way. Both footwells had some rusted out holes.

In that last photo you can see the beginning of spreader plates.

With spreader plates in, Dan starts to check fit for the cage itself.

Unhappily, the comfy seat we originally purchased for this project rides too tall, and too wide so we added more lightness with a Kirkey (and got to a seat that actually fits)

And so we progress ultimately to a fully welded and sorted roll cage. One of my favorite one-liners from the official Lemons Rulebook states:

3.5.1.2 What Do You Mean By All That Mumbo-Jumbo? Don’t understand any of the above? See where it states “professional-quality”? If you don’t understand this, you really shouldn’t be doing this yourself.

Well, we knew what the mumbo-jumbo meant, but had none of the skills necessary to implement it correctly. Always work with a professional if you, yourself, are not one. This isn’t something we really believe, we’re running Lemons, after all. But in the case of a cage, the one thing that protects our drivers more than anything else? Let’s not wing it.

Well, even professionals have accidents from time to time. Sadly, the installation took out our windshield. As you’ll see, trying to do this around and inside a windshield is no easy thing, and well, ours broke. This, however, greatly simplified the job of adding gussets to those parts of the cage behind the front glass.

As you may know, finding replacement windshields for 42 year old cars is, in itself, an adventure. In a future post and mastodon thread, I’ll share more about how we are going about it.

Now, a cage is important for safety. But it also adds stiffness. A stiffer body prevents flexing under stress, and massively improves handling of the vehicle. This is one of those happy coincidences, where the things you do that make you safe also make you faster and more maneuverable. We removed hundreds of pounds of weight, and added stiffness, all in the name of safety! Dan was also kind enough to add a strut bar brace for us for extra stiffness in the backend. Obvious jokes are always welcome.

We’ll explore Adventures in Windshield Replacement in an upcoming post. In the meantime, if you’re in the Denver area and are looking for some help with a cage, please reach out and we’ll happily connect you with Dan.

For now, enjoy some of the final shots of this incredible work.