All the gears restored

We rounded out the 2022 season successful but busted, and are in need of a new transmission. Or, if not new, then a transmission with all the gears. Happily, we had acquired a second-hand transmission from "this guy" on Craigslist. An early draft of this article read that we bought the transmission from "this guy" we met in the paddock. Such was my seemingly incorrect but very clear memory. I don't want to imply that the Lemons paddock is a place of shady auto-parts transactions peopled entirely with guys in trenchcoats full of transmissions walking around... On second thought, yes I do want to imply that, as while not strictly true it's not far from the reality. In any event, we had sourced a transmission of hopeful but questionable provenance.

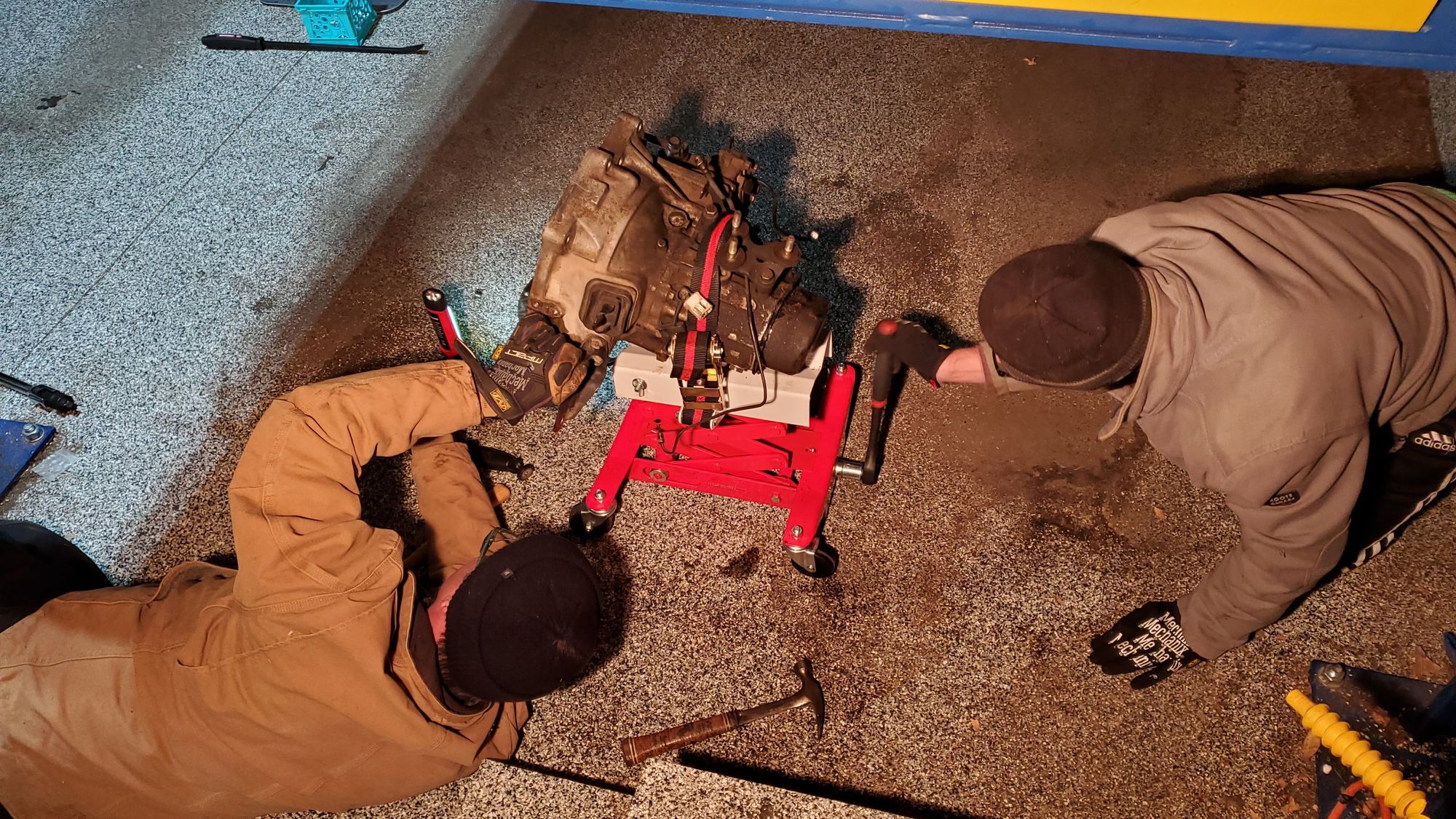

Having a replacement transmission is only half the solution, we also have to actually, physically replace the damn thing. Let's level set here: none of our team are mechanics. We're engineers, software dorks, manager types with equal portions of gumption and hope, but not tons of mechanical experience. Just scheduling a work night seemed daunting until an unnamed team member setup a weekly recurring Monday night for us to dig in.

The job itself, while daunting, really wasn't that hard. We had to remove the axles, the starter, some engine and transmission mounts, bits of suspension, several dozen bolts, a few sensors and ultimately the transmission. Then, just do all of that in reverse order and voila! One shiny new racecar.

A job like this presents plenty of opportunities for little upgrades along the way, and we took advantage of these to replace some aging engine and transmission mounts, as well as suspension bushings and of course our clutch. Other opportunities presented themselves like replacing the rear main seal, which we chose not to pursue {{foreshadowing intensifies}}.

It's worth mentioning at this point that we all live in Denver, Colorado. Our work nights for this job were in March. For most of the country this means Springtime. In Colorado it means 20 degrees or worse, and you may notice we are all wearing several layers. The job stretched out over 5 worknights, none of which involved jorts and t-shirts, our preferred shop attire.

As you can see in the video below, dropping the transmission is a very delicate process involving a lift, and gravity, some hope, and also more gravity.

With the transmission out, we're free to start swapping bits from the old to the new, and also replacing the clutch. Add this to the now growing list of "first time we've ever...." mechanical accomplishments. We're really unsure how many race hours this clutch had on it, and while it didn't look to be in terrible shape, given that we've already performed all the steps necessary to replace it, the incremental cost of the parts were easy to stomach. So: new clutch AND new(ish) transmission!

No plan long survives first contact with the enemy

Into every life, a little rain must fall. And so it is with transmission swaps also. I'll spare you, gentle reader, the long list of oopsies, part misorders, fluids i left at home, tools i forgot, and interruptions by adorable puppies that slowed us down. But let it suffice to say this job took longer for us based on plenty of little mis-steps.

While not excruciating, getting the transmission out was not horrid. We had, after all, one of the most reliable allies around at our side: gravity. As we were about to learn, working against that same ally is hard! But first let's get this thing prepped for install.

Sometimes, you can describe conceptually what's about to happen in utter clarity. You can picture the pieces coming together in your mind. You can rationalize how well it will all go, after all these parts were engineered to be serviceable, and to fit together in particular but achievable ways. Then, you find yourself twisted half sideways half upside down under a car with a 100 pound transmission above you. Two hours have passed in this position, and similarly uncomfortable and unproductive positions, and still the transmission will not go in.

Sadly our ultimate success here was not captured on camera or video. But, the key to victory lay in accidentally dropping the transmission off the support jack and onto an unnamed team member. After confirming he was not dead, he realized the transmission had landed in exactly the right angle necessary for mating with the engine. And so he did.

It would be hard to capture the elation we felt as the last few bolts were tightened on this, and it felt like the end of a long road. Underappreciated in that moment was the still quite long list of things that needed to be re-attached, assembled, installed and put back together before this car was driving anywhere.

While there were some tough moments, I'll summarize most of our frustration by saying simply: "those fucking axles". Hard to remove, harder to reinstall.

After the axles came the bushings. While not the hardest thing, that job coming last surprised us with the difficulty and time we had to get it done.

After all the thrashing and tears, we decided the car was as back together as she was going to be, and that those 3 extra bolts we found on the ground were probably not important. It's time to fire this baby up and see if she explodes!

She is Risen indeed. Long live Uma, glorious stallion that you are.